What is digital manufacturing example?

Modern examples include machines that can be manipulated by a human in 3D to simulate specific movements. This may interest you : The high cost of producing cheap food. The machine can then automate these same movements while evaluating and optimizing its performance.

What do you mean by digital production? Digital manufacturing is the use of an integrated computer-based system consisting of simulation, 3D visualization, analytics, and collaboration tools to simultaneously create product and production process definitions.

What are 2 examples of manufacturing?

Examples of production are automotive companies, bakeries, shoemakers and tailors, as they all create products rather than provide services. However, logging or mining, for example, is not production because it does not turn goods into new products.

What are the 3 types of manufacturers? See the article : Northridge: A sports boutique that accepts all great offers.

When we talk about the three types of production we ultimately mean, inventory (MTS), custom manufacturing (MTO), and assembly to production (MTA). These three types of production are quite common among producers.

What are 2 processes used in manufacturing?

Five types of production processes

- Repetitive production.

- Discrete production.

- Manufacture of workshops.

- Process production (continuous)

- Process production (batch)

Where is digital manufacturing used?

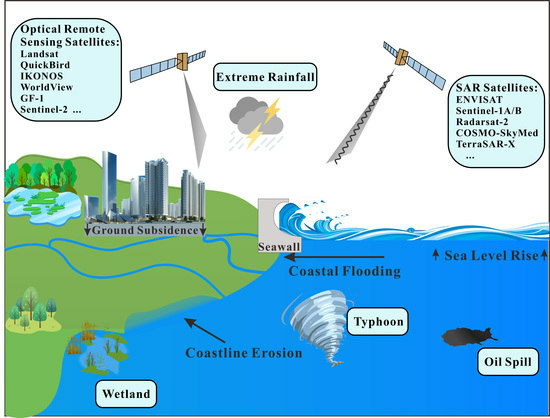

Industrial use Digital manufacturing is rapidly spreading to industries such as aerospace and defense. On the same subject : From retro to tech, Michigan drivers will get new license plate options. It enables the integration of supply networks through cloud computing so that suppliers can work together effectively.

What is digitalization in manufacturing?

There is a fourth industrial revolution: the digitalisation of production. This fundamental change, often referred to as “Production 4.0”, involves the integration of digital technologies, such as artificial intelligence (AI) and machine learning, with the amount of data now available to manufacturers.

What are 3 examples of technology used in manufacturing areas?

Some examples of advances in manufacturing technology include 3-D printing, robotics, and big data.

What are the examples of smart manufacturing?

10 examples of smart production technologies

- AI / machine learning. …

- Augmented reality / virtual reality. …

- Automation / robotics. …

- Production of additives / hybrid production. …

- Big data analysis. …

- Cloud computing. …

- CNC machining. …

- Design for production.

Who uses smart manufacturing?

Kayla Matthews says Amazon and Adidas are not the only success stories of smart production. Whirlpool, Siemens, HP, Hirotec and Ocado are defining industrial processes in new and innovative ways.

What are four smart manufacturing elements?

Smart manufacturing means bringing elements of smart technology – sensor inputs, computing power, always-on connectivity, artificial intelligence and advanced data analytics – into the traditional manufacturing process.

When did the digital manufacturing concept?

When did the concept of digital production become prominent? Explanation: The concept of “digital production” became prominent in the early 1970s. It became famous after the publication of Computer Integrated Manufacturing by Dr. Joseph Harrington.

Why is digital production important? Digital manufacturing is a fully integrated approach that manufacturers can use in planning, scheduling, quality management, cost control, material flow, and workshop. This means that manufacturers can turn to digital technology to make their stores more efficient.

What is digital transformation in manufacturing?

Digital transformation of production means improving traditional production processes, products and workforce with digital technologies such as automation software, e-commerce, sensors, industrial robots and more.

What are the 6 core elements of digital transformation?

6 Digital Transformation Components

- Innovation. …

- Cooperation. …

- Experience. …

- Infrastructure modernization. …

- Operational excellence. …

- Information and reviews.

What are the three 3 main components of digital transformation?

Managers are digitally changing the three key areas of their business: customer experience, business processes and business models. And each of these three pillars has three different elements that change. These nine elements form a set of building blocks for digital conversion.

What advanced digital manufacturing?

Advanced manufacturing involves the use of innovative and advanced technology to improve products and processes by enhancing the cyber-physical integration of production. This includes digitization and automation through the use of devices, sensors and robotics in work processes.

What is a digital manufacturing engineer?

Coordinating, facilitating, and implementing a digital manufacturing strategy to meet and accelerate our current business needs (productivity, flexibility, time to market, training, quality compliance, etc.).

What is digital design and manufacturing?

Digital Design and Manufacturing Through artificial intelligence (AI) innovation, integrated planning and management, and additional manufacturing, organizations can create a wider range of products and dramatically reduce the time it takes to design complex systems designed.

How AI is transforming manufacturing?

Artificial intelligence in manufacturing can enable the digital transformation of industry into a more efficient, skilled and productive version. This can help improve accounting, inventory management and supply chain flow. By analyzing machine data, it can also significantly improve the health of the machine.

How is artificial intelligence used in production? Manufacturers use artificial intelligence technology to detect possible downtime and accidents by analyzing sensor data. AI systems help manufacturers predict when functional devices will fail or fail so that maintenance and repair can be scheduled before a failure occurs.

How artificial intelligence affects the manufacturing industry?

Artificial intelligence enables machines to collect and extract data, recognize patterns, learn and adapt to new things or environments through machine intelligence, learning and speech recognition. Using artificial intelligence, manufacturers can: create fast, data-driven decisions. Facilitate better production results.

How artificial intelligence is transforming manufacturing?

The McKinsey report suggests that AI can improve forecasting accuracy in production by 10-20%, which means a 5% reduction in warehousing costs and a 2-3% increase in revenue. Other benefits of AI in manufacturing include: predictive maintenance to reduce unplanned downtime.

How AI builds a better manufacturing process?

For manufacturers, artificial intelligence is also coming into play through a new process called generative design. Here’s how it works: Designers or engineers enter design goals into generative design software – along with parameters for materials, manufacturing methods, and cost constraints.

What is the role of artificial intelligence in manufacturing?

The use of artificial intelligence allows manufacturers to predict when or if functional devices will fail so that maintenance and repairs can be planned in advance. This is important because using predictive maintenance based on artificial intelligence can make machines work more efficiently – and more cost-effectively -.

How AI can contribute to the industry beyond manufacturing?

Big data and artificial intelligence are giving the industry a huge boost 4.0. Intelligent software solutions can use the large amounts of data generated by the factory to identify trends and patterns that can then be used to streamline production processes and reduce energy consumption.

How has artificial intelligence impacted manufacturing?

61 percent of industrial manufacturing executives say productivity gains are the biggest potential benefits of introducing AI, and a majority (95 percent) agree that AI technology would make their business more efficient.

What is direct digital manufacturing?

DDM is the seamless production of components from computer design to the actual part. Also known as “3D printing” or “additive”, “fast”, “fast”, “on-demand” production, DDM uses 3D computer design files to control the computer-controlled fabrication of parts.

What are digital production applications? This allows companies to better understand, evaluate and optimize their processes. The virtual and physical worlds may collide with augmented reality technology. In industries, employees can manage production processes and improve decision-making.

What mechanism is used in digital manufacturing?

However, every digital production process involves the use of computer-controlled numerical control (CNC) machines. This technology is crucial in digital manufacturing, as it not only enables mass production and flexibility, but also provides a link between the CAD model and production.

Which are offerings of digital manufacturing and operations?

What are the best software systems for digital production?

- Computer aided design (CAD) software. CAD software is a mature market segment. …

- 3D printing. …

- Industrial robotics. …

- Product Lifecycle Management (PLM) …

- Internet of Things (IoT) …

- Artificial Intelligence (AI) …

- Cloud computing. …

- Create a digital infrastructure.

What is DDM manufacturing?

DDM is the seamless production of components from computer design to the actual part. Also known as “3D printing” or “additive”, “fast”, “instant”, “on-demand” production, DDM uses a 3D computer. auxiliary design files to control the computer-aided fabrication of parts.

What are the Industry 4.0 applications today?

10 real-world industry 4.0 technology examples

- Big Data & amp; Analytics.

- Autonomous robots.

- Simulation / digital twins.

- Horizontal and vertical systems.

- Internet of Things (IIoT)

- Cyber security technology.

- Cloud.

- Manufacture of additives.

What are the uses of Industry 4.0? Industry 4.0’s main goal is to make manufacturing – and related industries such as logistics – faster, more efficient and more customer-centric, while going beyond automation and optimization and discovering new business opportunities and models.

Which features of Industry 4.0 are changing our lives?

For example, smart factories, the Internet of Things, robots, location recognition technologies, advanced human-machine interfaces, 3D printing, augmented reality, big data, and 3D technology are reshaping the way companies produce and how customers search for products. , communicate and buy products.

What is Industry 4.0 how it will impact our lives?

Industry 4.0 is not just about the potential increase in resource efficiency in manufacturing or the robust collection of data. This is already happening and will affect your life through improved products and services, road safety, better working conditions and even health.

What is Industry 4.0 What is its significance in today’s world what are the important features?

Industry 4.0 technology helps you manage and optimize all aspects of your production processes and supply chain. It gives you access to the real-time data and insights you need to make smarter and faster decisions about your business, which can ultimately increase the efficiency and profitability of your entire business.

What are Industry 4.0 initiatives?

Industry 4.0 marks a new phase in the industrial revolution, with a strong focus on connectivity, automation, machine learning, and real-time data.

What is Industry 4.0 and how does it work?

Industry 4.0 is revolutionizing the way companies produce, improve, and market their products. Manufacturers are integrating new technologies, including the Internet of Things (IoT), cloud computing and analytics, and artificial intelligence and machine learning into their manufacturing facilities and operations.

What is an example of the Industry 4.0 revolution?

Autonomous robots. Simulation / digital twins. Horizontal and vertical systems. Internet of Things (IIoT)