HAMBURG, Germany – The automotive industry has always been a major consumer of textiles, but it is deepening its ties with specialist fabric companies, including those linked to fashion.

Polestar, the Sweden-based subsidiary of China’s Geely Holding Group, was a key supporting partner of the Global Fashion Summit, held in Copenhagen, Denmark in June. The company wants to find new sustainable materials to produce a car that will leave the factory gates with a zero-carbon footprint by 2030.

While the existing Polestar 2, a 5-door liftback electric vehicle designed to house the Tesla Model 3 head-on, comes with vegan textile seats (no leather or animal products in the finish), the Polestar 5, due out in 2024 is to have their seat covers manufactured using an innovative 3D knitting process that avoids waste.

This system is already being used in the fashion and footwear industries, for example to produce products for major fashion brands such as Uniqlo and Adidas, according to Polestar. The material mix of the Polestar 5 seats will include recycled plastic bottles, flax fiber and recycled natural cork from the wine industry.

The company also wants to promote sustainability for interiors with animal products: “Although only 5% to 10% of our customers choose leather, we are working to make leather more sustainable and only source it from certified sources as a waste product of the meat industry” , a Polestar spokeswoman tells Wards.

She says the company uses a chrome-free production method that uses natural sources of probiotics, enzymes and plant-based polymers, as well as plant-based and synthetic tanning agents. “Grass feeding and regenerative farming practices are used throughout the supply chain,” she adds.

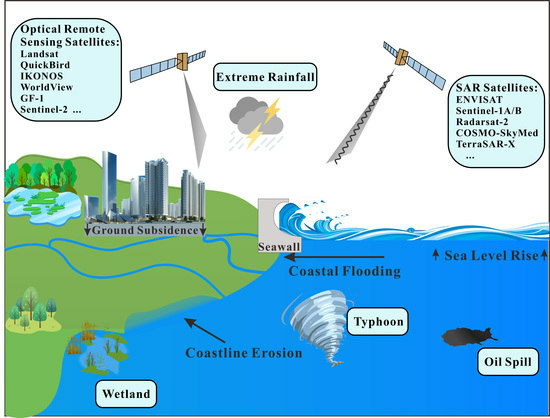

UK-based luxury brand Lotus, also owned by Geely, will launch its Lotus Eletre in 2023, a battery-electric luxury CUV that integrates an advanced wool-blend fabric on its seats (pictured above), which are 50% lighter than traditional leather, allowing for further weight savings. For its part, German automaker Audi uses recycled plastic bottles, which are ground into polyester yarn, which makes up 89% of its fourth-generation A3 car seat material.

Ferdinand Dudenhoeffer, professor at the Center for Automotive Research at the University of Duisburg-Essen, in Germany, states: “Volvo, Tesla, BMW, Audi and Co. are all moving away from leather seats, which reflects the issue of the circular economy, which is increasingly being incorporated into their marketing concepts .”

He calls Mercedes (pictured below) “the notable exception” and says: “It is unsustainable to waste the skins of cows after slaughter for meat production.” switch to using only sustainably produced and processed leather for all our models. It involves everything from raising cattle to tanning.” The company requires that its entire leather supply chain be free of illegal logging and that no natural forests are cleared for land grazed by Mercedes leather cattle.

Tanning agents must be vegan or completely chrome-free, for example from dried coffee beans or chestnuts. Mercedes is also researching vegan alternatives to real leather, for example using renewable raw materials such as powdered cactus fiber or mushroom mycelium (the root-like structure of a mushroom).

Dudenhoeffer downplays the widespread notion that China, a major auto market not known for prioritizing sustainability over glamor and comfort, will never embrace vegan car seats at the expense of leather, and says Tesla, as a key opinion leader in China, is likely to have influence Younger Chinese drivers are more receptive to the green transition.

“(China’s President) Xi Jinping may prefer leather, but if the boss of ‘Automaker X’ prefers vegan, it will be interesting to see where the Chinese consumer trend will go,” says Dudenhoeffer.

On the R&D front, the state-funded Taiwan Textile Research Institute (TTRI) in Taiwan is developing water-based leathers with long-term thermoregulation using temperature-reactive phase change material (PCM) materials and water-based microencapsulation technology. These innovative materials have been used extensively in home furnishing products, but the institute has pilot small-scale production underway for car seats.

The PCM materials coated with microcapsules are highly thermally conductive and can easily be added to leather coatings. The technology absorbs external heat and converts it into phase change energy, allowing leather temperatures to be maintained between 27°C and 31°C (80.6°F to 87.8°F) significantly longer when exposed to sunlight than untreated leather. The microcapsule shells are made from solvent-free, water-based polyurethane resin that is free of volatile organic compounds, heavy metals and formaldehyde.

“The more PCM added to the leather, the better the heat buffering effect,” Lin Po-Ju, head of applied materials department at TTRI, and Huang Chung-mou, deputy engineer at TTRI, tell Wards. “The leather can be designed with different thicknesses, embossing and softness and is particularly suitable for long journeys for all types of RVs, commercial vehicles and electric vehicles.”